|

|

| Our Products | |||||||||||

|

|

CNC Plasma Cutting Machines

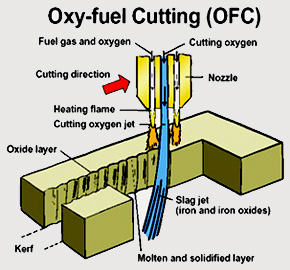

> Cutting Techniques > Oxy-Fuel Oxyfuel cutting is a combustion process using oxygen/fuel gas flame. In the first step, the temperature of the steel must be rizen to the ignition temperature. Afterwards, an oxygen jet oxidizes the metal in the narrow section and cuts a kerf, removing the slag from the kerf.

Oxyfuel cutting is a combustion process using oxygen/fuel gas flame. In the first step, the temperature of the steel must be rizen to the ignition temperature. Afterwards, an oxygen jet oxidizes the metal in the narrow section and cuts a kerf, removing the slag from the kerf.

Oxy-fuel cutting can be used for mild and low-alloy steel in a material thickness up to several decimetres. The quality of the cut depends on the surface condition of the material, cut-velocity and thickness. Characteristics: Plate thickness: 3 mm up to 2800 mm Typical: 10 mm up to 300 mm Review: - Moderate cut quality - Smooth, vertical planes of cut - Metallurgical perfect surfaces (oxidized) - Carbonizing and hardening within the area of the heat affected zone - High heat input - Limited range of material - Low cutting speed |

| The Company | Our Products | Services | Distributors | Glimpses | Contact Us | Home |